The History of Dennis

Dennis as a company started life at the end of the 19th Century when brothers Raymond & John Dennis set up in business together manufacturing motorised tricyles in Guildford. Dennis as a company started life at the end of the 19th Century when brothers Raymond & John Dennis set up in business together manufacturing motorised tricyles in Guildford.

They then moved into quadracycles and soon after cars. This was a time of rapid development and innovation. In 1901 the two brothers set up Dennis Brothers Limited. Development was rapid and soon their innovation led to producing commercial vehicles as well as cars. Lorries, vans, buses and fire engines were all in production by World War 1.

After the war demand for lorries dropped off and the company adopted an aggressive development strategy producing new products for the post war world. After the war demand for lorries dropped off and the company adopted an aggressive development strategy producing new products for the post war world.

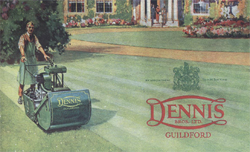

In 1922 the Dennis Motor Lawn Mower was announced. The company was already doing a lot of business with the local authorities so it was a logical step as they were responsible for looking after many acres of public parks.

The mowers were innovative too and Dennis were the first motor mower manufacturer to include a differential in the rear roller allowing it to be turned without marking the grass.

Quick to see the benefits Dennis’ brochure claimed the mower could do in 3.5 hours a job that would take two men and a horse 7 hours.

By 1925 Windsor Castle was a Dennis Mower user as were many of the fine houses and estates around Great Britain and the Colonies. By 1925 Windsor Castle was a Dennis Mower user as were many of the fine houses and estates around Great Britain and the Colonies.

Initially Dennis used bought in engines from firms such as Blackburn & Bradbury but by 1934 Dennis was producing its own engine due to the high demand for its quality machines.

Mowers were exported around the world to every corner of the empire and beyond. In just 12 years the market had expanded tremendously and everyone was demanding the coveted Dennis stripe.

During World War II Dennis produced thousands of lorries, fire fighting pumps along with a wide range of military equipment including the assembly of Churchill Tanks.

In 1945 the war was over and production of buses, lorries, fire engines and mowers picked up again.

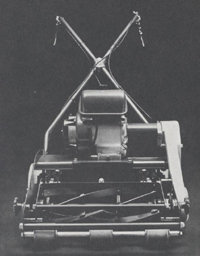

By the late 1950’s the traditional Dennis Mower was becoming outdated relying on 1920’s technology which whilst strong and reliable did not reflect modern manufacturing techniques. By the late 1950’s the traditional Dennis Mower was becoming outdated relying on 1920’s technology which whilst strong and reliable did not reflect modern manufacturing techniques.

The Premier mower was developed in the late 1950’s using a more modern 600cc single cylinder crank start engine made by Dennis. The Wipac or Lucas Magnetos remained an important feature.

In 1962 the Premier collected a gold medal at Southport Flower Show. The range was limited to 24”, 30” and 36” machines and the decision was taken to develop Guildford Gang Mowers to trail behind the seat of the Premier.

The 20” and 24” Paragon were also bought into production utilising the Villiers C30 engines.

The Swift and Swallow rotary mowers were introduced – not made by Dennis – but branded products. The 1960’s were turbulent times and Dennis Bros Limited were finding it difficult to survive. By the end of the decade it had stopped bus production. Its new updated trucks failed to make any significant impact on the haulage market.

The company took the decision to concentrate on its strongest products – municiple vehicles and fire appliances but these were low volume, high labour input and the company struggled to make ends meet. The company took the decision to concentrate on its strongest products – municiple vehicles and fire appliances but these were low volume, high labour input and the company struggled to make ends meet.

In early 1972 the company was bought by Hestair (after a vigorous defence by the Dennis board) and mower manufacturing was moved from Guildford to Kent.

Subsequently around 1976 the motor mower division was sold to one of the subcontractors Godstone Engineering at Godstone, Surrey. Production of Premiers and Paragons continued there whilst the Guildford gang mower divisions was sold to Howardson Ltd (formerly Howards Engineering).

Howards had at that time of the sale put a bid in for both motor mower and gang mower division but were not successful in the motor mower side. Howards had at that time of the sale put a bid in for both motor mower and gang mower division but were not successful in the motor mower side.

By 1981 Godstone Dennis was in difficulties due to dropping sales and a lack of new product to fight the competition. The firm was sold to Howardson later that year and all stock and production moved to Derby.

Howardson, established in 1938 by Wilfred Howard was a third generation family engineering business looking to expand to its own product lines. With over 45 years of engineering experience in subcontract manufacture and jig and tool work the Dennis acquisition was a great move.

Since 1981 investment in design has been paramount Premiers and Paragon machines were revamped to accommodate reliable Kohler electric start engines superceded by Kubota petrol and diesel power units.

New products were developed and in the late 1980’s Marathon Mowers of Portway, Birmingham were purchased giving a broader product base of verge and rough cut machines. These machines were based on the famous Wolseley Clearway.

In 1988 Dennis started to import and badge Kaaz rotary mowers from Japan to fulfil a demand for rotary mowers from Local Authorities. Whilst a good solid machine the strong Yen and fierce competition led to the project being discontinued by 1990.

Dennis acquired the design rights to Seymour Sports Ground rollers of Derby from Castwell foundry and a range of powered rollers was produced from early 1990’s to 2003 when low volumes meant it was no longer viable to continue. Dennis acquired the design rights to Seymour Sports Ground rollers of Derby from Castwell foundry and a range of powered rollers was produced from early 1990’s to 2003 when low volumes meant it was no longer viable to continue.

In 1990 Howardson purchased JP mowers from Cliftons of Woking who had bought the company from the receivers of JP Engineering, Leicester back in 1972. JP had been a victim of the Rolls Royce collapse of 1971 as they had been a major supplier of machined components to them.

The JP mower had a reputation as the ‘Rolls Royce’ of domestic lawnmowers and many hundreds of machines are still in use today. Their range originally covered from 10” push mowers through to 24” self propelled cylinder mowers.

Co-incidentally JP had started producing mowers in 1922 the same year as Dennis.

The acquisition was a great boost to Howardson who saw the potential of the machine to fill the gap in the bowls, cricket and golf market that the traditional Dennis products had never filled.

The JP cassette system, originally designed in the early 1960’s was the basis of the design for scarifiers, vericutters, brushes and a multitude of other options.

This concept was the basis of the FT430, 510 and 610 as well as the Supersix.

In the late 1990’s the G Series was developed with the arrival of a new design engineer. This included a suite of machines including the Sport, G560 & G680 as well as the cassette machines the G760, G860 and Contractor.

The next six years saw a period of strong growth as Dennis products sold into the broader market.

The rights to Bray seed slotters and spiking equipment was acquired from Dave Bracey in 2002 and subsequently a powered slotter spiker design developed by Mr Gwyn Jones of Didcot Bowls Club was acquired. This forms the basis of the popular S500 machine.

Design and development are still at the forefront of our ethos. New products are in development and exciting products continue to be improved.

Customer feedback is critical to our success and many of our designs are as a direct result of our discussions with groundsmen, greenkeepers and gardeners.

|